(The price is per board BUT we only sell them in packs of 5 so you must round up or down to the nearest 5 - 5, 10,15,20 - its not 5 boards for £5)

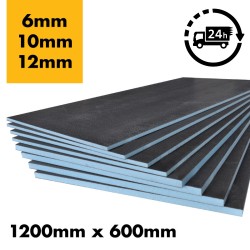

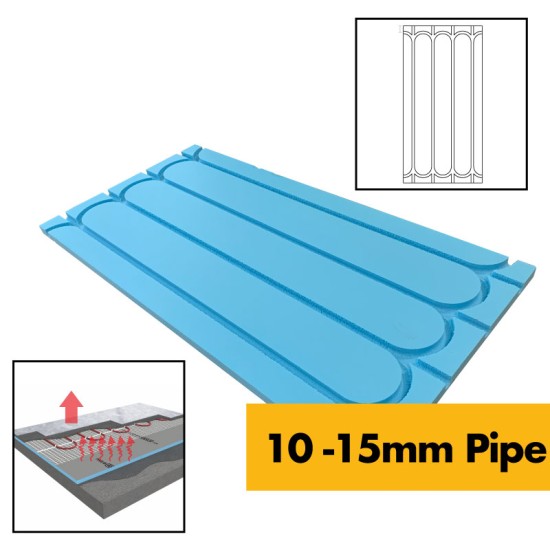

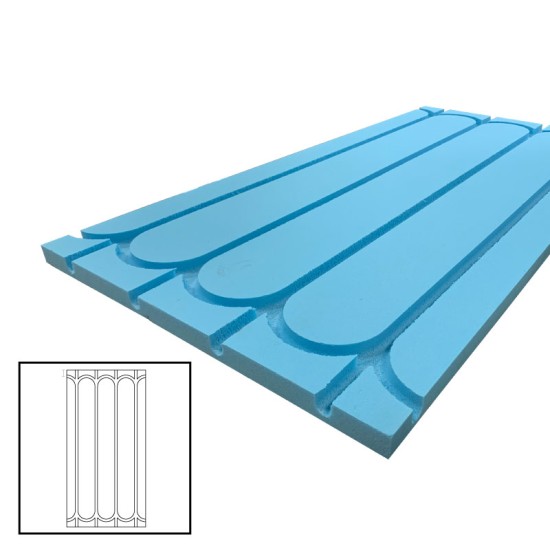

25mm XPS foam insulation underfloor heating (UFH) boards for 10-15mm flexible pipe wet system underfloor heating. High compressive strength of 400 kpA ideal to accommodate a variety of floor coverings, for wooden/laminate floors or to be tiled onto directly (porcelain/ceramic tiles)

[Low profile at 20mm only 20mm thick] Save cost and space with these 20mm thick XPS foam insulted boards for wet underfloor heating systems meaning floors dont need to be dug/relayed, can simply be played over the existing substructure

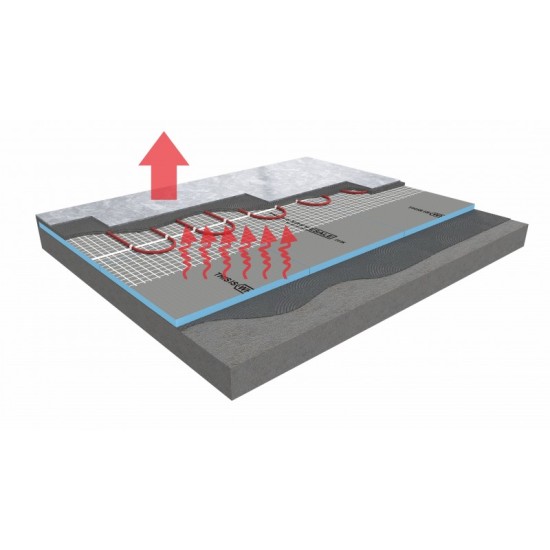

[Energy saving keeping heat in the room/above surface - U Value 1.55W/m2x K] Make your wet underfloor heating system more energy efficient and save cost / reduce heat loss into the sub floor, efficient heat transfer and optimal performance of your wet underfloor heating system

[Lightweight, Easy to lay, cut with a Stanley knife & quick to install] Our Innovate pre-cut 16mm channels are suitable to accommodate 10-15mm flexible pipes. They are simple to cut to size at edges / corners, and 1200mm x 600mm size at 0.72m2 coverage means you can cover large areas quickly and efficiently

[Speeds up your underfloor heating installation] Simply lay the 10-15mm flexible pipe in the precept channels, saves time and cost on other systems securing each run of pipe mechanically or with track work. Each board cuts with channels recut for a U/180˚ return (ie. At a wall) or a straight through run to the next board - Pipe centres spacing spacing 150mm

[Suitable for Tiling or wooden/laminate floors] The textured surface of our XPS foam insulated underfloor heating boards make them ideal for applying flexible tile adhesive directly to the board. Furthermore, the high compressive strength of 400 kPa mean you can simply lay wooden/laminate flooring systems directly on top (relevant underlay recommend as per flooring manufacturers instructions)

Board Features & Benefits:

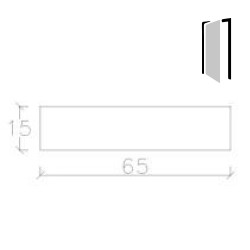

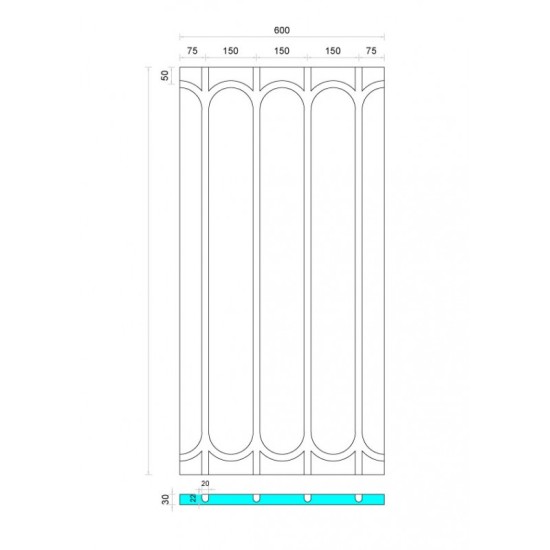

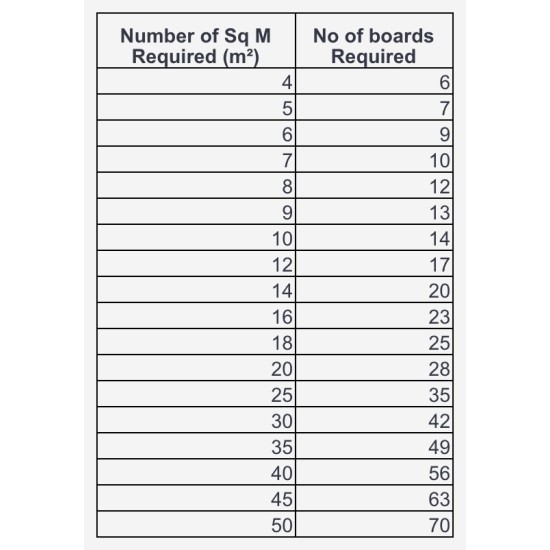

- 1200 x 600mm +/-5% tolerance Boards (individual board size) which makes it very easy to transport and move around on site - Price is for each board which is 0.72 sq m (you need 1.4 x boards to cover 1 sq m - we recommend ordering +10% to allow for wastage / offcuts etc.)

- 20mm thick - pipe channel centres 150mm

- Good insulation - reducing condensation - makes it a great surface to fit wet underfloor heating (UFH) systems onto & non-conductive surface reduces condensation by masking any cold bridging from the substrate beneath

- <0.1 vol % Moisture Absorption

- Has a high compressive strength of over 30 Tonnes per sq.m making it incredibly strong

- High compression strength and lightweight

- Compressive Strength (10% deflection to EN 826:1996) Minimum of 0.3N/mm2

- Flammability to EN 13501-1 Class E

- Impact Sound Reduction (BS-ISO140-8) 21 dLw

- Density 36kg/m3 (DIN 53420)

- Bending Stiffness, E( 20mm / 30mm) 601KNmm2 / 1285 kN/mm 2

- Seal edges with foil aluminium tape

| Number of Sq M Required (m²) | No of boards Required |

| 4 | 6 |

| 5 | 7 |

| 6 | 9 |

| 7 | 10 |

| 8 | 12 |

| 9 | 13 |

| 10 | 14 |

| 12 | 17 |

| 14 | 20 |

| 16 | 23 |

| 18 | 25 |

| 20 | 28 |

| 25 | 35 |

| 30 | 42 |

| 35 | 49 |

| 40 | 56 |

| 45 | 63 |

| 50 | 70 |

Boards are price individually and only sold in packs/multiples of 5 hence you may need to round up to the nearest 5 ie. 5, 10, 15, 20, 25 etc...

Property | Assessed to | Rating | ||||||

| Density | DIN 53420 | 32 kg/m3 | ||||||

| Thermal Conductivity (initial) | DIN 52612 | 0.034 Watt/mK | ||||||

| Thermal Conductivity (>5yrs) | ASTM C518 | 0.036 Watt/mK | ||||||

| Compressive Strength (10% deflection) | DIN 53421 | Minimum of 0.3N/mm2 | ||||||

| Flexural Strength | ASTM C203 | 0.30 ±0.02 MPa | ||||||

| Water Absorption (2-day immersion) | ISO2896 | 0.2% by volume | ||||||

| Water Absorption (Capillary) | DIN 53428 | Zero | ||||||

| Coefficient of linear expansion | N/A | 70 x 10-6 K-1 | ||||||

| Water Vapour Diffusion Resistivity (µ) | DIN 52615 | 110 - 225 µ | ||||||

| Water Vapour Permeability | ASTM E-96 | 0.028 ng/Pa.m.s | ||||||

| Fire Euroclass | BS EN 13501-1 | Class E |

Installation

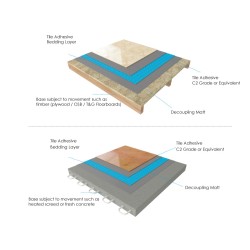

The installation method for XPS foam insulation boards depends on the type of heating system being installed:

- Wooden floor Heating System: Lay the boards in a staggered brick bond pattern, optional foal tape joints end edges, then place the heating mat directly over the boards

- Tiled floor - suitable for concrete subfloors only - the boards must be securely fixed to the subfloor using a suitable flexible tile adhesive. This ensures stability and proper heat distribution